Tooling Rapid & Production

Get an instant quote for you

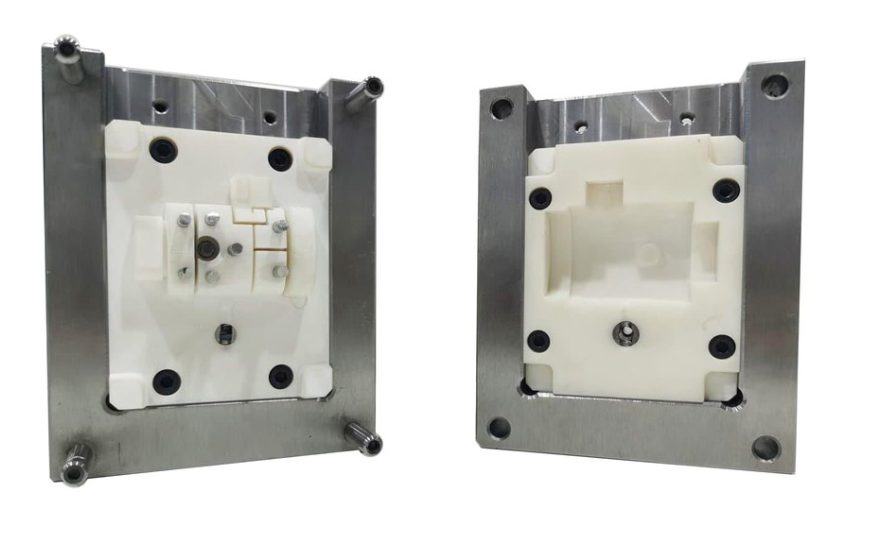

Rapid tooling offers a solution to trial tools and produces short production runs of parts from 1-100,000 units. Enabling the ability to deliver programs and customer value faster than ever before. Creating highly customized parts on-demand, reducing our reliance on expensive tooling with long lead times. This, in turn, enables greater design flexibility and faster response times to meet customers needs and market trends.

Our technology enables you to quickly prototype and test parts, allowing for rapid iteration and refinement of designs, ultimately leading to better end products.

This not only improves sustainability but also increases efficiency and profitability. Reducing time to market & cost to the planet.

We can produce tooling for a range of machines up to 1,700 tonne of pressure.

Investing in the very latest efficient machinery ensures we provide consistent high standards together with high quality, cost effective products.

From high volume production to short specialised runs, we’re able to adapt rapidly to customer requirements.

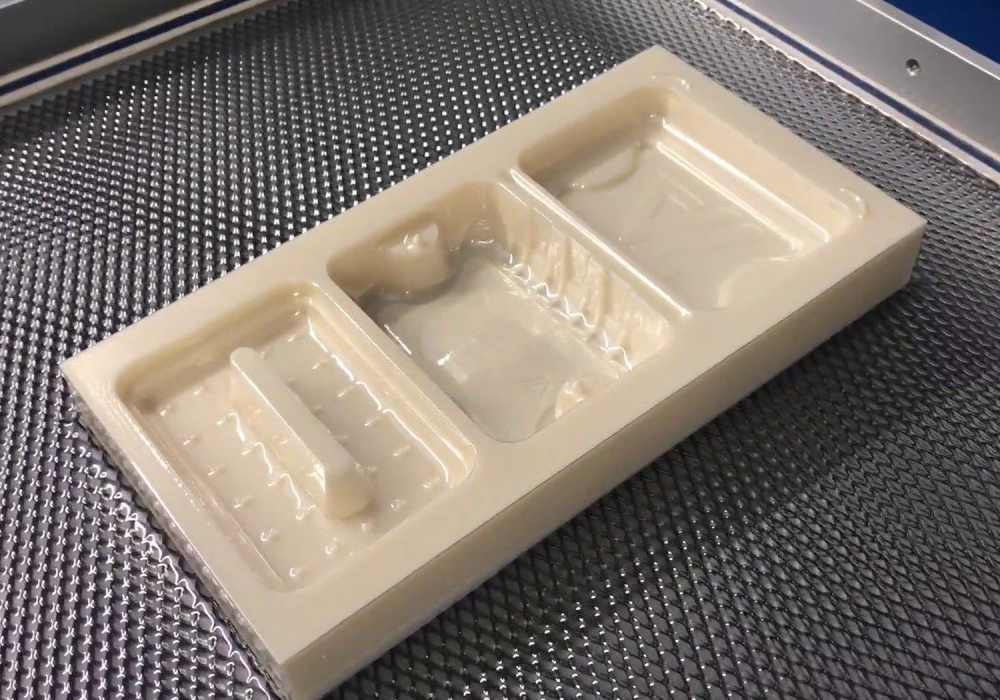

Vacuum Form tooling from small moulds up to 2 Metre Mouldings.

A variety of materials & the ability to also print trimming tools for post form CNC Trimming.

Intuitive tooling process using analysis driven design.

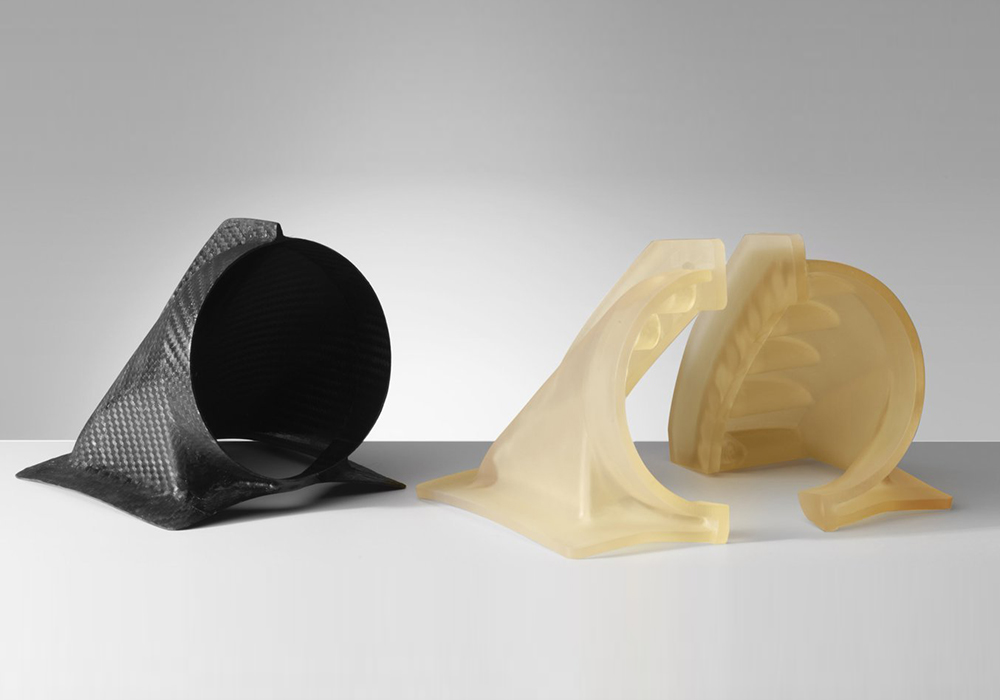

We can produce tooling for a range low & higher volume tools to produce carbon fibre components. Tools are produced quickly & effectively using our tooling resins.

Tools dependent on technology are capable of up to 150-200 Pull off’s of final parts.

This can also be used to produce insert tooling for traditional moulds.