Zero Tooling Cost

Get an instant quote for you.

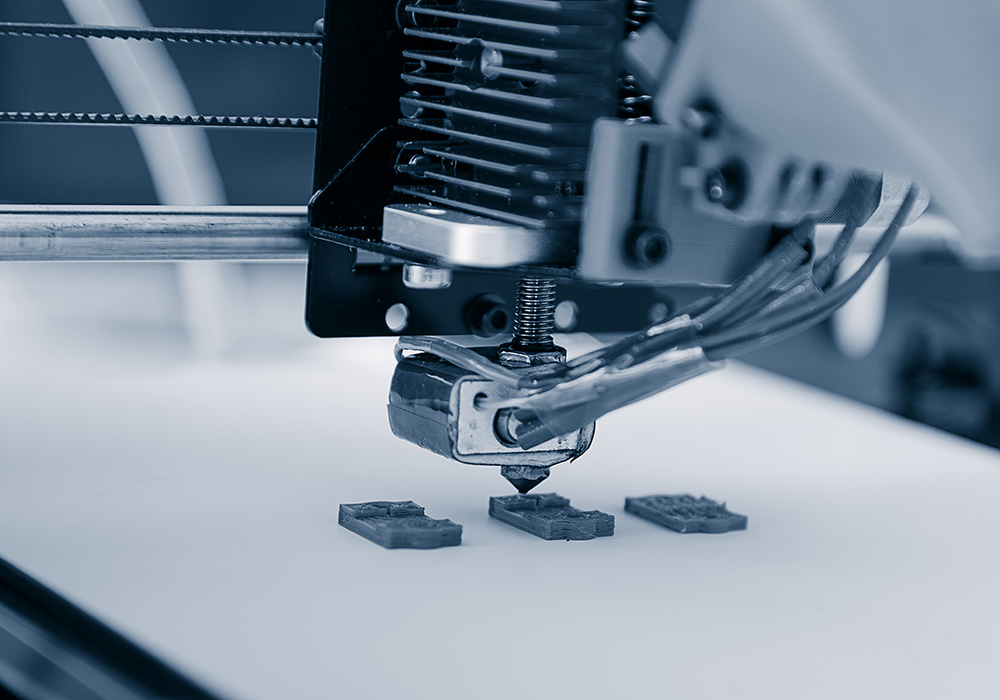

At Ryse3D, we believe that 3D printing represents a revolutionary step forward in the world of manufacturing. One of the key benefits of this technology is that it eliminates the need for costly and time-consuming tooling processes.

Traditional manufacturing methods, such as injection molding, require the creation of expensive tooling in order to produce parts. This tooling can be costly to produce and can take several weeks to manufacture, which can slow down your product development timeline.

With 3D printing, there is no need for tooling, as the parts are produced directly from the 3D design file. This means that there is zero cost for tooling, and that you can go from design to finished part in a fraction of the time it would take with traditional methods.

In addition to reducing costs and speeding up your product development timeline, 3D printing also provides greater design freedom, allowing you to create complex geometries and shapes.

At Ryse3D, we use state-of-the-art 3D printers to produce high-quality parts with precision and accuracy. Whether you're looking to create prototypes, or need to produce high-volume production runs, our 3D printing capabilities mean that you can get the parts you need, without the need for costly and time-consuming tooling.

Get in touch with us today to learn more about how 3D printing can help you streamline your product development process and bring your ideas to life.