MJF 3D Printing Service

Our MJF (Multi Jet Fusion) production line delivers high-precision, end-use polymer parts using advanced HP additive-manufacturing technology. It’s designed for customers who need accurate, repeatable, and production-ready components straight off the printer.

At RYSE 3D, we run HP PA11 and PA12 materials to suit a wide range of functional applications:

- PA 11 (Bio-based Nylon 11) – High ductility, excellent impact resistance, and superior fatigue performance. Ideal for automotive interiors, snap-fit parts, protective housings, and flexible clips.

- PA 12 (Nylon 12) – Outstanding dimensional stability, fine surface finish, and durability under load. Perfect for enclosures, manifolds, tooling, and low-volume production parts.

Our in-house finishing options include bead blasting, dyeing, vapour fusing, machining, and inspection, ensuring every component meets production standards.

Max Part Size 380 x 380 284mm

⚙️ Key Features of HP MJF 3D Printing

- High-detail, isotropic parts with exceptional dimensional accuracy

- Production-grade materials - PA11 and PA12 for strength, flexibility, and durability

- Consistent quality at scale - ideal for low to high-volume manufacturing

- Smooth, semi-matte surface finish straight off the build

- Excellent mechanical performance with minimal post-processing

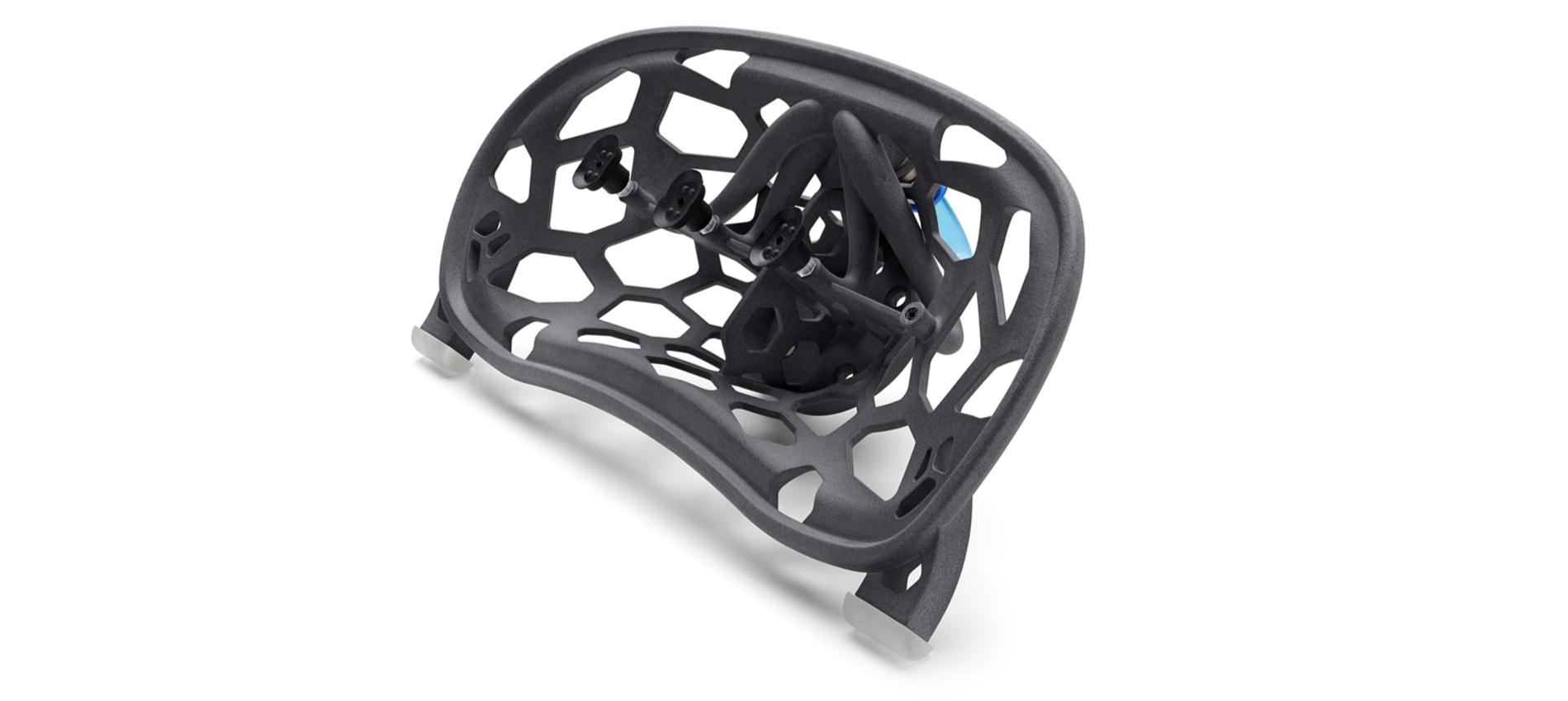

- Design freedom for complex geometries and consolidated assemblies

- Fast turnaround times with full in-house production and finishing

- Made in the UK - backed by the King’s Award for Enterprise in Innovation

MJF PA12 - Key Technical Specs

Material Type: Nylon 12 (Polyamide 12)

Technology: HP Multi Jet Fusion (MJF)

Colour: Grey (naturally) or Black (dyed)

Finish Options: Shot Peened as Standard | Vibro Polished | Vapour Smoothed

Heat deflection temperature: 175°C

Elongation at break: 15%

Tensile strength: 48 MPa/6960 psi

Tensile modulus: 1800 MPa/261 ksi

MJF PA12 Ideal Applications

- Functional Prototypes

- End-Use Production Parts

- Jigs, Fixtures & Tooling

- Fluid & Air Handling Components

- Custom and Replacement Parts

✅ In summary:

HP MJF PA12 is ideal for functional, load-bearing, and production-grade parts especially where strength, precision, and repeatability are critical. It’s one of the most versatile and scalable 3D printing materials for transitioning from prototype to production.

MJF PA11 - Key Technical Specs

Material Type: Nylon 11 (Polyamide 11 - Bio Based)

Technology: HP Multi Jet Fusion (MJF)

Colour: Grey (naturally) or Black (dyed)

Finish Options: Shot Peened as Standard | Vibro Polished | Vapour Smoothed

Heat deflection temperature: 183°C

Elongation at break: 35%

Tensile strength: 50 MPA/7250 psi

Tensile modulus: 1800 MPa/261 ksi

MJF PA11 Ideal Applications

- Functional Prototypes

- Flexible & Moving Components

- Medical, Orthotic & Prosthetic Devices

- Industrial & Tooling Applications

- Sustainable Manufacturing & Bio-Based Products

- Custom and Replacement Parts

✅ In summary:

HP MJF PA11 is the ideal choice when flexibility, toughness, and sustainability are key. Enabling production-ready parts that perform reliably across automotive, medical, and industrial sectors.

Trusted by World Leading Brands

PPAP Approved Automotive Parts

Production 3D Printers

Materials Available

Average Delivery from Order

Maximum Part Size - 260mm x 260mm x 310mm

Vapour Fusing - Enhanced Surface Finish Parts

💬 MJF 3D Printing FAQs

What is MJF 3D printing and how does it work?

MJF (Multi Jet Fusion) is an advanced powder-based 3D printing process developed by HP. It uses precision inkjet arrays and infrared fusing energy to build parts layer by layer, creating dense, isotropic components with consistent mechanical properties in all directions. It’s ideal for functional prototypes and end-use production parts.

What makes MJF different from other 3D printing technologies?

MJF (Multi Jet Fusion) delivers exceptional accuracy, detail, and consistency, making it ideal for production-grade polymer parts. It uses a unique powder-bed fusion process to create dense, isotropic components with smooth surface finishes and fine feature resolution.

What materials can RYSE 3D print with MJF?

We offer PA11 and PA12 as standard — two high-performance nylons used across automotive, aerospace, and consumer industries.

- PA11: flexible, sustainable, and impact-resistant.

- PA12: strong, rigid, and highly dimensionally stable.

Both are perfect for functional, production-grade applications.

How accurate are MJF 3D printed parts?

MJF delivers exceptional dimensional accuracy, typically within ±0.2 mm, and an extremely consistent surface finish. The process produces parts that are ready for use straight off the build, with minimal post-processing required for most applications.

How quickly can MJF parts be produced and delivered?

At RYSE 3D, we can produce and ship MJF parts in as little as 1–3 days. Our in-house production workflow is optimised for rapid turnaround while maintaining repeatable, production-grade quality at any scale.